Displaying items by tag: HEPA

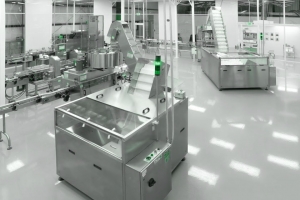

The Challenge of Working in a Cleanroom

Typically used in manufacturing or scientific research where small particles can adversely affect the processes, a cleanroom is a controlled environment that has a low level of pollutants such as dust, airborne microbes, aerosol particles and chemical vapors. Cleanrooms maintain particulate-free air through the use of either High Efficiency Particulate Air (HEPA) or Ultra-Low Penetration Air (ULPA) filters employing laminar or turbulent air flow principles.

Commonly Overlooked Cleanroom Dangers

It seems like in a cleanroom, it’s almost impossible to over think every move and decision you make. Sometimes people make mistakes they couldn’t have anticipated until they happen. Here are 5 common dangers that not everyone is cognizant of when working in a cleanroom.

Cleanroom Design Impacts Classification

Clients often come to me specifically requesting an “ISO 7 cleanroom” or an “ISO 8 cleanroom.” What they often fail to realize is that the ISO class does not define the layout of the cleanroom. It only defines the cleanliness level that needs to be met. In fact, the ISO classification actually corresponds to a specification of how clean the cleanroom must be. The ISO 14464-1 standard doesn’t say how to design the cleanroom, it only specifies the maximum quantity of air particles allowed.

Cleanroom HEPA filters specifications

HEPA filters, as defined by the United States Department of Energy (DOE) standard adopted by most American industries, remove at least 99.97% of airborne particles 0.3 micrometers (µm) in diameter. The filter's minimal resistance to airflow, or pressure drop, is usually specified around 300 pascals (0.044 psi) at its nominal flow rate.

Cleanroom High Efficiency Particulate Air

High efficiency particulate air (HEPA), originally called high-efficiency particulate absorber but also sometimes called high-efficiency particulate arresting or high-efficiency particulate arrestance, is a type of air filter. Filters meeting the HEPA standard have many applications, including use in medical facilities, automobiles, aircraft and homes. The filter must satisfy certain standards of efficiency such as those set by the United States Department of Energy (DOE).

Cleanroom Certification

A cleanroom is an extremely purified region in which temperature the air quality and humidity are kept under strict management. The atmosphere in the cleanroom is filtered to remove other contaminants and dust particles. Cleanrooms are primarily employed for production equipment which is sensitive to contaminants, including hard disk drives, silicon chips, microprocessors and integrated circuits. Cleanroom certification comprises examining the room for assorted parameters, including static electricity, airborne particles, relative humidity, temperature and differential pressure.

FRP/C-PVC Modular Cleanrooms

FRP and C-PVC Cleanrooms provide the ideal contamination-free processing environment for bio or pharmaceutical and other operations requiring an environment that's easy to clean and sterilize.

Clean Room Terminology

What is a Cleanroom?:

An enclosed area that’s controlled environmentally over atmospheric contamination, temperature, pressure and, often, humidity.

What is a Cleanroom Air Lock:

A room attached to the Cleanroom. This room has interlocking doors and its function is to act as a buffer zone between the cleanroom and the outside atmosphere, during the transfer of material or personnel. It helps keep the cleanroom pressurized and free from infiltrating dirt.

Key Elements of Contamination Control

We will look at several areas of concern to get a better idea of the overall picture of contamination control. These are the things that need to be considered when providing an effective contamination control program.

Cleanroom Overview

Cleanrooms can be very large. Entire manufacturing facilities can be contained within a cleanroom with factory floors covering thousands of square meters. They are used extensively in semiconductor manufacturing, biotechnology, the life sciences, and other fields that are very sensitive to environmental contamination.