Displaying items by tag: standards

What Are the Different Types of Clean Room Classes and Standards?

A cleanroom is an environment that must maintain a specific concentration and size of airborne particles per cubic meter. To achieve and maintain a specific cleanliness classification, the room is supplied with a continuous supply of HEPA filtered air.

Cleanroom: A Comprehensive Guide to Design, Standards, and Applications

A Comprehensive Guide to These Essential Environments for High-Precision Manufacturing and Research, Highlighting the Applications, Maintenance and Cleaning Practices

The Standards and Other Basics of Cleanroom Design

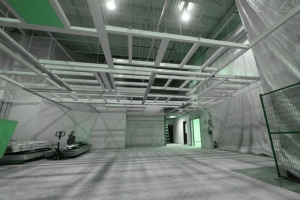

Cleanrooms are an important component of industrial manufacturing and laboratories, used extensively within the technology, pharmaceutical and medical industries. Accordingly, a cleanroom design must be created according to exact requirements that are spelled out in internationally recognized standards. This blog is a first in a series discussing the design and construction of cleanrooms and will cover these standards, the utility matrix that guides the design process, and the equipment included in the mechanical systems that support the cleanroom. Future blogs will discuss mechanical equipment in depth, examine how to maintain the quality of the air within the cleanroom and review the protocols that must be maintained during construction to insure the integrity of the finished cleanroom.

The Ultimate Guide for Designing a Manufacturing Cleanroom

Designing a manufacturing cleanroom is a critical step in ensuring the company’s output consistently meets targets without major quality issues. Being thoughtful about the room’s design can reduce problems like static and particulate matter contamination that could otherwise harm products.

Cleanroom: A Quick Guide To Classifications, Design, And Standards

Cleanrooms are integral to countless operations around the world. Scientists, manufacturers, and a bevy of other industry professionals rely on these rooms to mitigate the risk of contamination in products or processes. It’s important to understand the different cleanroom classifications and guidelines behind how these rooms are constructed and utilized to determine which is the best fit for your application.

About cleanroom design

The biggest source of contaminants in any industry is air. In order to minimize the amount of particles floating around, production processes are moved to a cleanroom.

Cleanroom Design: Let the Standards Guide You

Perhaps the popular view of a cleanroom is as a stark, cold antechamber where brave biocontainment specialists don slightly trimmed versions of spacesuits and battle novel pathogens threatening to escape clandestine BSL-4 facilities. In the movies, and sometimes in real life, that may be true. However, cleanrooms pervade research, testing, and industrial facilities, with prominent roles in pharmaceutical and semiconductor manufacturing, food safety, immunosensitive research and clinical care, and mobile or temporary applications that require pop-up and tear-down capabilities. Consequently, they run the gamut from moderately restrictive additions within permissive facilities, to isolated and sterile environments that function like giant, single-purpose biosafety cabinets.

Cleanroom Industry Standards

Cleanrooms are essential to any manufacturing process where particulate contamination can affect the quality of goods produced. Cleanrooms provide secure environments with controlled air filtration, lowering the possibility of product contamination or large particulate interference with critical process manufacturing. Cleanrooms are used in industries such as medical device manufacturing, food processing, computer manufacturing and server holding, military and aerospace research and life sciences as well as thousands of other potential applications.

Cleanroom standards

It is some years since the ISO 14644 and 14698 series of international cleanroom standards started taking over from national standards. Early parts are already undergoing their statutory five-year reviews; other parts have only recently been published and new parts are still being written.