Displaying items by tag: build

Everything You Need to Know About Building a Cleanroom

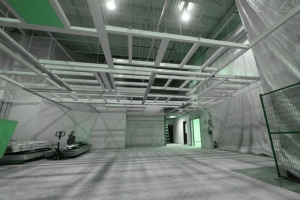

Cleanrooms provide a safe and controlled environment for laboratories and other workplaces that require clean areas for employees who are handling certain substances or materials. These areas are also designed to protect delicate equipment from damage. When it comes to building a cleanroom, there are standards that should be applied in order to ensure an environment that is as clean as possible. Learn more about cleanroom construction standards and other elements of cleanroom design.

Cleanroom Design and Construction: Best Practices and Considerations

Cleanrooms are critical spaces in many industries where it is essential to maintain a controlled environment to prevent contamination of products or experiments. From pharmaceuticals to microelectronics, cleanrooms play a crucial role in ensuring product quality and safety.

Clean Room Design And Build Considerations

Reliable cleanrooms are specially constructed, enclosed spaces designed to regulate airborne particles, temperature, humidity, air pressure and more. As a leader in designing and assembling ISO class-compliant cleanrooms, Clean Air Products takes industry-regulated requirements into consideration when creating high-performing, aesthetically appealing cleanrooms. We design and manufacture Federal Standard 209E-compliant recirculating and non-recirculating modular hard wall and soft wall cleanrooms in a range of standard and custom sizes and configurations based on your specific industry requirements.

ISO Clean Room Standards and Other Classifications: Design, Redesign & Compliance

ISO Clean Room Standards and classifications are one of the most complex – yet essential – parts of designing and building a clean room. There are many important questions that need to be asked when planning for, designing and setting up your clean room. In this blog we explain how hygiene automation equipment can reduce or eliminate the risk of cross-contamination and bioburden while meeting clean room design requirements.

How to Design a Clean Room in a Regulated Facility

“Room in which the concentration of air-borne particles is controlled, and which is constructed and used in a manner to minimize the introduction, generation, and retention of particles inside the room, and in which other relevant parameters, e.g. temperature, humidity and pressure, are controlled as necessary”.

Clean Room Design And Build Considerations

We are specially constructed, enclosed spaces designed to regulate airborne particles, temperature, humidity, air pressure and more. As a leader in designing and assembling ISO class-compliant cleanrooms, we takes industry-regulated requirements into consideration when creating high-performing, aesthetically appealing cleanrooms. We design and manufacture Federal Standard 209E-compliant recirculating and non-recirculating modular hard wall and soft wall cleanrooms in a range of standard and custom sizes and configurations based on your specific industry requirements.

The Considerations of Building a Cleanroom

An integral part of scientific research, yield optimisation, safety assurance and quality control, cleanroom installation is an increasingly important feature within the manufacturing process.

About cleanroom design

The biggest source of contaminants in any industry is air. In order to minimize the amount of particles floating around, production processes are moved to a cleanroom.

Cleanroom Design: Let the Standards Guide You

Perhaps the popular view of a cleanroom is as a stark, cold antechamber where brave biocontainment specialists don slightly trimmed versions of spacesuits and battle novel pathogens threatening to escape clandestine BSL-4 facilities. In the movies, and sometimes in real life, that may be true. However, cleanrooms pervade research, testing, and industrial facilities, with prominent roles in pharmaceutical and semiconductor manufacturing, food safety, immunosensitive research and clinical care, and mobile or temporary applications that require pop-up and tear-down capabilities. Consequently, they run the gamut from moderately restrictive additions within permissive facilities, to isolated and sterile environments that function like giant, single-purpose biosafety cabinets.

Designs for GMP Clean Rooms

A cleanroom (GMP cleanroom), in my mind, is a combination of engineering design, fabrication, finish and operational controls (control strategy) that are required to convert a “normal” room to a “clean room”. This blog will attempt to explain the necessary characteristics of a regulated company clean room not producing potent chemicals or active or hazardous biologicals. If there are significant containment requirements, the requirements would be outside the scope of a “simplistic” blog like this. In a pharmaceutical sense, clean rooms are those rooms that meet the code of GMP requirements as defined in the sterile code of GMP, i.e. Annex 1 of both the EU and PIC/S Guides to GMP and other standards and guidance as required by local health authorities.