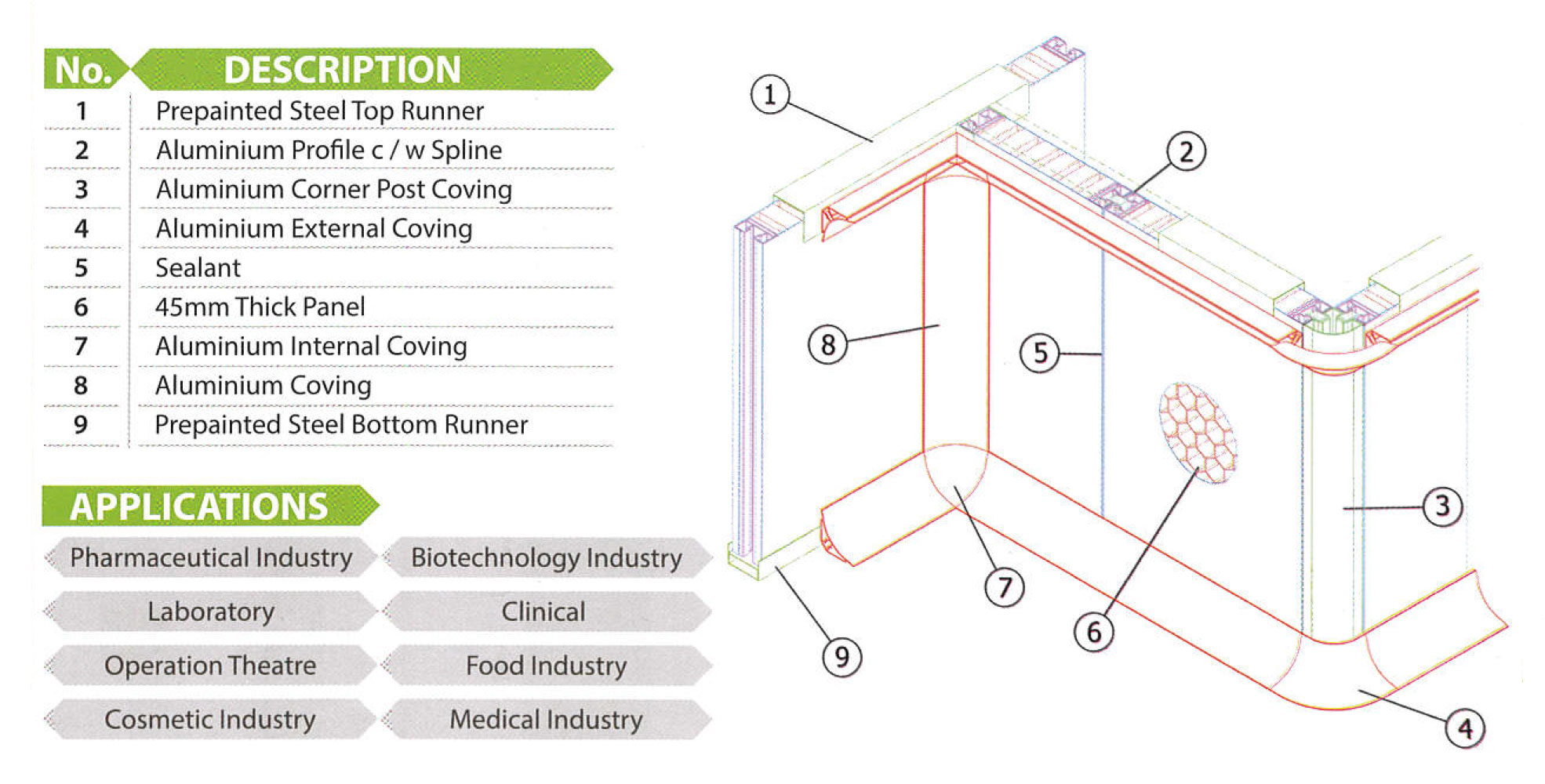

45mm Flush Wall Partition Systems

CLIN® Flush Wall Partition System Panel consists of rolled-edge top and bottom steel or aluminium skins bonded to an aluminium honeycomb core for a total thickness of 45mm with aluminium perimeter frame bonded between the skins. Designed specifically for life science and pharmaceutical applications that require a flush wall surface with radius corners which promotes ease cleaning.

The pre-engineered CLIN® flush partition panels head track consists of a U-shaped prepainted steel track, which is attached to the underside of the ceiling panel system. By sliding the top panel edge can be fabricated from various cores and lamination skins to suit various cleanroom applications up to Class 1 classification & GMP requirement.

CLIN® Wall Partition System is tested and classified by the Malaysian Fire Department as Class “O” material in accordance with British Standard series BS 476 Part 6: 1989 and BS 476 Part 7: 1997, FM Approved.

“A wide range of CLIN® door sets and single-glazed or double-glazed windows are also available to complement the CLIN® flush partition systems.”

The pre-engineered CLIN® flush partition panels head track consists of a U-shaped prepainted steel track, which is attached to the underside of the ceiling panel system. By sliding the top panel edge can be fabricated from various cores and lamination skins to suit various cleanroom applications up to Class 1 classification & GMP requirement.

CLIN® Wall Partition System is tested and classified by the Malaysian Fire Department as Class “O” material in accordance with British Standard series BS 476 Part 6: 1989 and BS 476 Part 7: 1997, FM Approved.

“A wide range of CLIN® door sets and single-glazed or double-glazed windows are also available to complement the CLIN® flush partition systems.”

Engineered Design

Progressive studless wall panel with aluminium perimeter frame edges are tightly engaged to adjoining panels with a fixed aluminium spline. When fully engaged, this spline joint provides structural continuity and integrity between the adjacent panels compliant to GMP requirement.

Corrosion Free

Attractive Finish

Easy Installation

Specification

| Skin | Prepainted Steel Sheet, Prepainted Aluminium Sheet, G.I Sheet & Stainless Steel Sheet |

| Colour Finishing | White RAL 9016, Clean White and Cardamine White (Optional: Static dissipative 106 - 109 Ω |

| Standard Size | 1.175m ~ 1.2m (W) x 3m ~ 5.7m (H) x 45mm (T) |

| Supporting Structure | The system incorporates an aluminium perimeter frame bonded between the skins to provide additional support and the panel edges are tightly engaged to adjoining panels with a fixed aluminium spline to provide a rigid and sealed connection |

| Design | Progressive and Flush Design |

| Structural Material | Aluminium extrusion alloy 6063-T5 |

| Accessories Finishing | Natural Anodised, Electro-Deposition or Epoxy Powder Coating |

| Cleanroom Application | Up to Class 1 classification, Compliant to GMP requirement |

| Variation of Colour | Delta E ≤ 1 |

| Malaysian Fire Department | Class “O” |

- Tested & certified under SIRIM QAS International Fire Listing Scheme.

- Tested by TÜV SÜD PSB (Singapore), FM Approved.

- No exposed fasteners on partition panel after installation completed.

- Available with single-glazed or double-glazed windows.

Internal Core Material & Lamination Skin

1 |

Aluminium Honeycomb (A-Comb)Internal Core Material |

|

2 |

Paper Honeycomb (P-Comb)Internal Core Material |

|

3 |

Polystyrene (PS)Internal Core Material |

|

4 |

Mineral Wool / Rock WoolInternal Core Material |

|

We are experienced in Cleanroom Solutions

Call us for consultation +604 398 1778