Displaying items by tag: isolator

Isolators Advantages & Limitations

Isolator systems can provide an alternative to the standard International Organization for Standardization (ISO) Class 5 cleanrooms used in aseptic filling applications.

Isolators Manual Operations

In isolator processes requiring manual control, workers can typically gain access to the products within the enclosure through the use of a half-suit or glove ports.

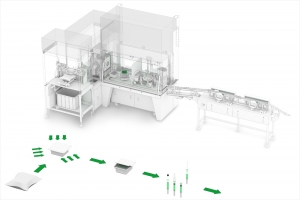

Isolators Filling & Transfer

During filling operations in an isolator, sterilized products or containers are transferred into the unit through rapid transfer ports, airlocks, or similar controlled openings. Rapid transfer ports sometimes feature systems for sterilizing incoming components using heat.

Isolator Configurations

The majority of isolators come in either a closed or open form. Closed isolators are completely sealed, blocking any contaminated or unfiltered air from entering the enclosure during operation. These units provide the most effective protection from airborne impurities, but can be relatively slow for production or processing work.

Cleanroom Isolators

In an industrial cleanroom environment, unidirectional air flow can provide a component or process with protection from airborne contaminants, but additional measures may be required to block these types of contaminants in certain applications. Barriers between the contamination source and the process, product, or personnel in the cleanroom can effectively shield sensitive elements. In addition to cleanroom garments, curtains, and structures, clean air devices, such as transfer hoods, safety cabinets, and isolators can be used to achieve the necessary level of contaminant control. These devices usually have their own air filtration units independent of cleanroom ventilation and can provide workspaces that are some degree cleaner than the larger cleanroom itself.